Wind turbine components manufacturing

The internal structural design of modern wind turbines forms an extraordinarily complex system, both mechanically and electrically. The interior of the tower is made up of welded structural elements, these platforms are located on several levels in the tower. The structures are basically made of structural steel, and their weather resistance is ensured by a hot-dip galvanized coating. Our plant currently manufactures more than 30 types of such structures, our experienced team has the flexibility to mass-produce structures of various shapes and sizes, which we manufacture to strict quality requirements meeting delivery deadlines.

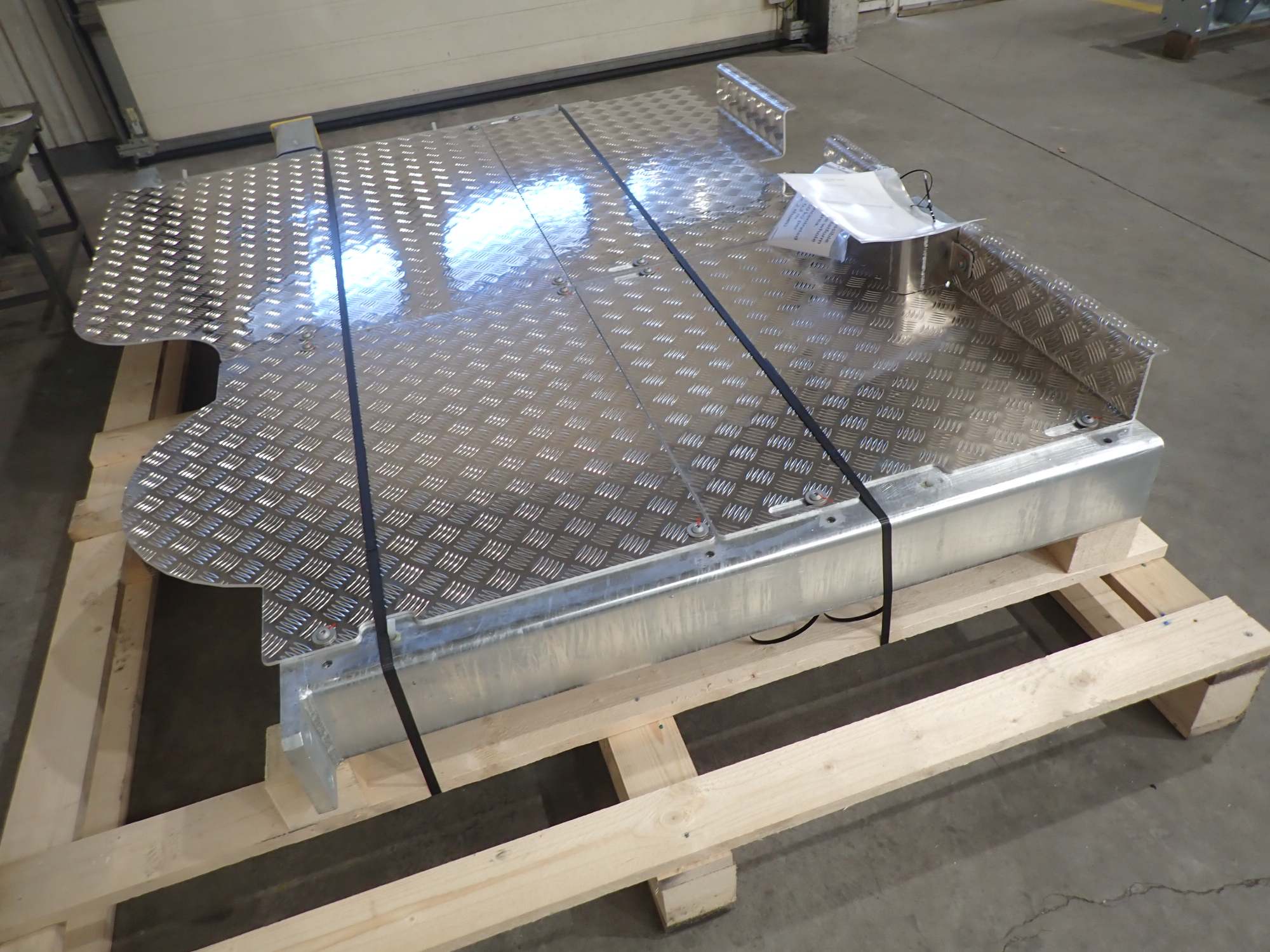

The interior of wind turbines is also made from more complex, larger welded structural components, which are then modularly assembled with other large turbine components during the final assembly. The structures here are already more complex and robust, weatherproofed also with a hot-dip galvanized coating, but aluminum components and fasteners with a special coating also appear. Our plant can move and machine such a structure up to 3t, our experienced team also performs the pre-assembly and packaging of the products, using special large pallets, which we also make on-site.