Always Superior Performance!

Meet Us at MRO AMERICAS!

Welcome to the World of Aero Space Power!

Aero Space Power is a dynamically growing company that primarily offers MRO solutions for the aviation and energy industries. With many years of experience in aircraft and energy servicing, we have been working with GE Power for a long time and hold a long-term maintenance service agreement with GE Aviation.

We provide excellent manufacturing solutions, comprehensive engine component refurbishment, and repair services for the world’s largest turbine manufacturers and MRO service providers. We can confidently say that we possess the solutions and expertise.

We also aim to strengthen our position in the industrial gas turbine sector, a market segment experiencing dynamic growth. This is a significant step in ensuring the company’s continued development.

VISION

Regional leader in maintenance, repair, and overhaul for aerospace and energetics.

PURPOSE

We are building a resilient company through devoted competence.

UNIQUENESS

We have a resilient portfolio!

Complex projects with industry leaders of Aviation MRO, Energy and Renewables.

GEOGRAPHY

Save time and cost!

Excellent location in Europe with FAA, EASA, CAAC, UK CAA certificates.

COOPERATION

Trust in your partner!

We invest & You win our Reliability – Flexibility – Expertise.

COOPERATION

Trust in your partner!

We invest & You win our Reliability – Flexibility – Expertise.

GEOGRAPHY

Save time and cost!

Excellent location in Europe with FAA, EASA, CAAC, UK CAA certificates.

CAPABILITIES

Aviation

Since September 2019, we have held the European Union Aviation Safety Agency (EASA) Part-145 maintenance organization certification with a C7 rating. In March 2021, we obtained the Federal Aviation Administration (FAA) 14 CFR Part 145 repair station approval. Additionally, as of December 2024, we have been approved by the Civil Aviation Administration of China (CAAC) as a Part 145 repair station for engine and component maintenance.

These certifications reflect our expertise and dedication to complying with global aviation standards.

Aero Space Power Ltd. is committed to meeting the highest quality standards in the aerospace industry, as evidenced by our numerous international certifications.

CAPABILITIES

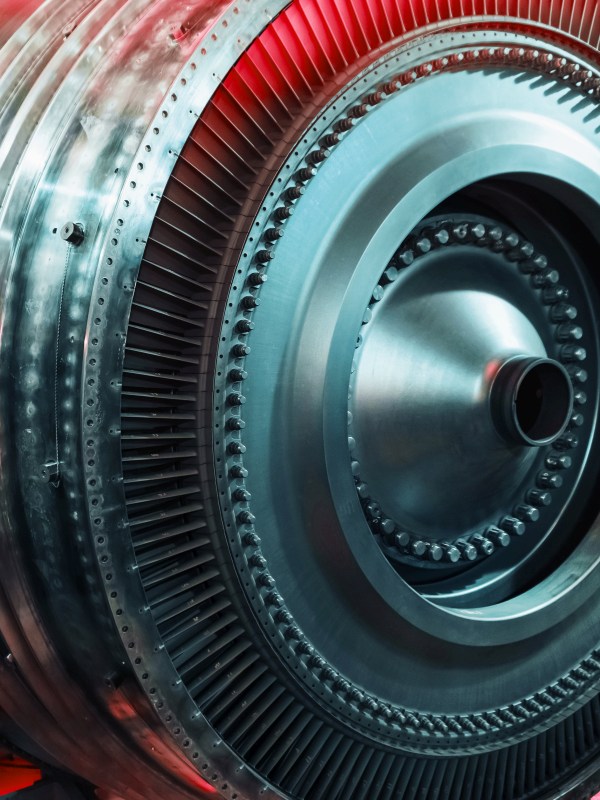

Energy

Our services include the maintenance and production of various components, all of which meet the industry’s most stringent standards. Our experienced engineers and technicians utilize cutting-edge technologies to deliver the best solutions to our clients, contributing to the long-term, uninterrupted operation of gas turbines.

We take great pride in our long-term partnership with industry leader GE Vernova, which further strengthens our position in the field.

The repair and manufacturing of gas turbine components play a crucial role in power generation, ensuring the reliability and efficiency of engines.

CAPABILITIES

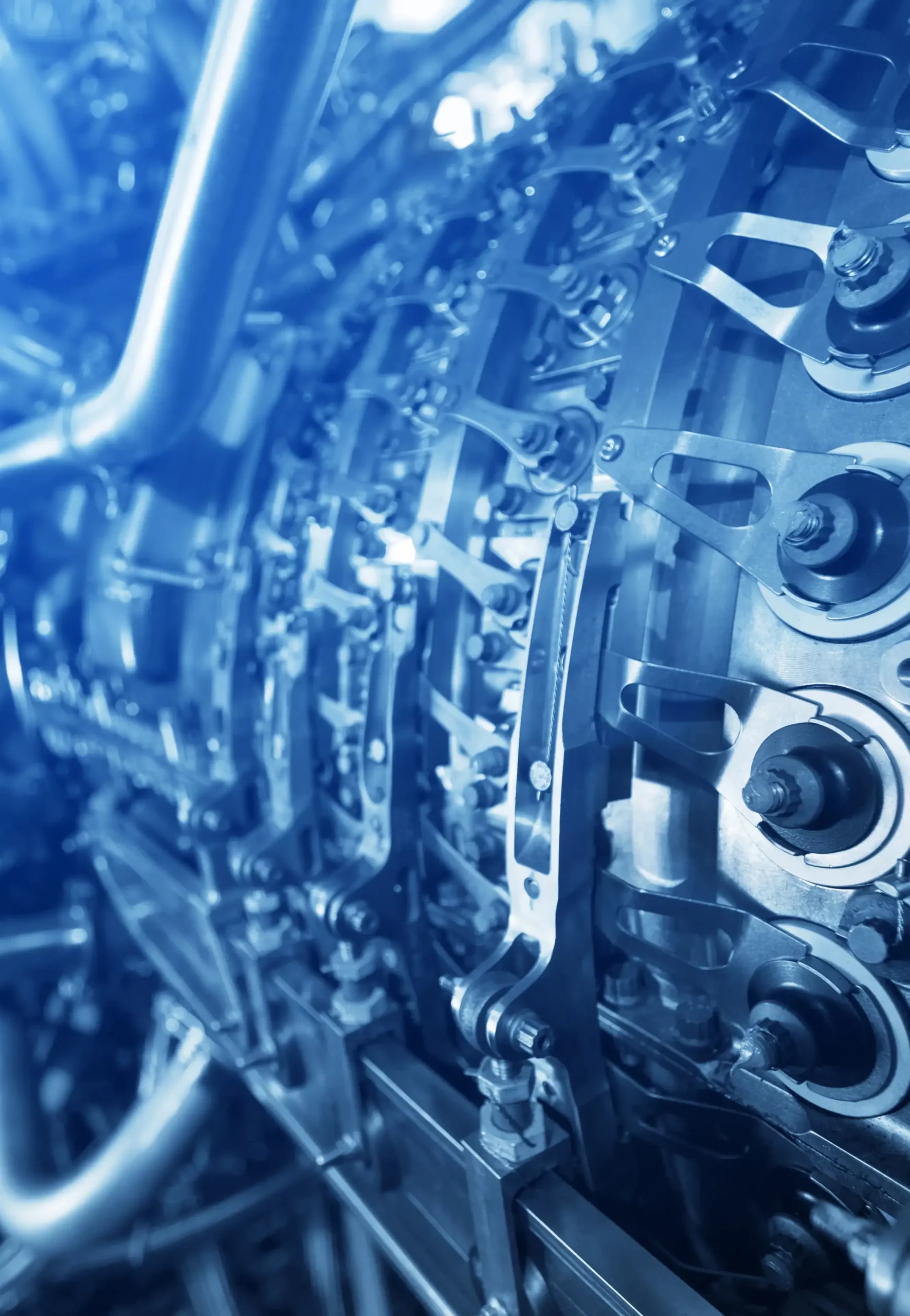

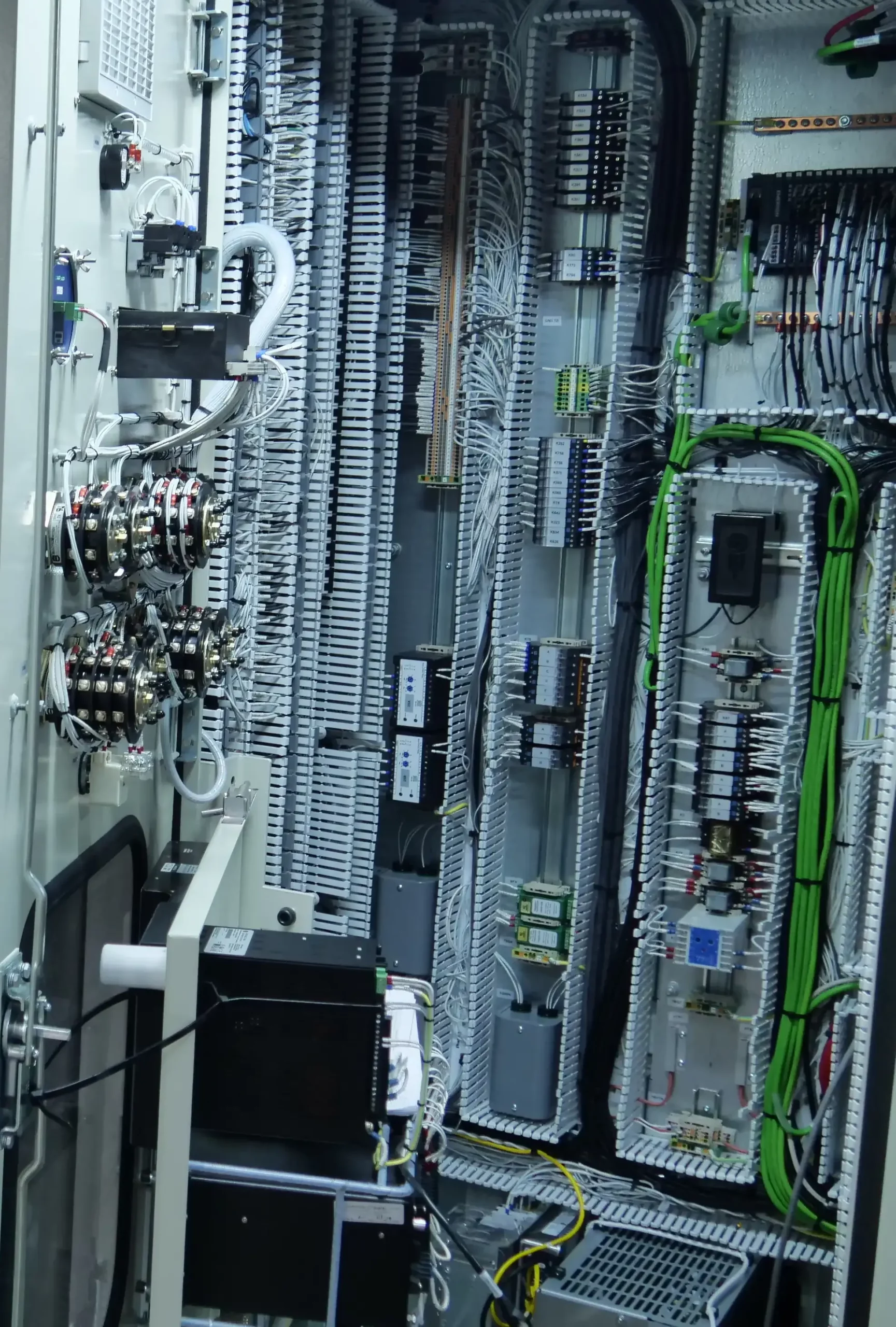

Complex Solutions

We have the expertise to execute complex projects, including welding, painting, manufacturing/procurement of equipment and components, as well as control cabinet assembly and wiring.

With our end-to-end project management, we ensure efficient and timely execution of every project. Our customer-focused approach and flexibility allow us to deliver tailor-made, complex solutions from start to finish.

We proudly collaborate with renowned companies such as GE Vernova and GE Wind, working together on innovative projects in the fields of energy and technology.

Our company offers comprehensive solutions in electronic control systems, energy, telecommunications, and welded structures.

CAPABILITIES

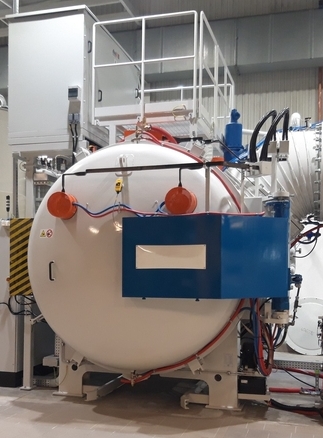

Vacuum Heat Treatment

This advanced technology allows metal components to be heated in an oxygen-free environment, enhancing their mechanical properties and surface quality.

At Aero Space Power, we utilize this technology across multiple sectors, including aerospace and gas turbine engine component heat treatment as part of our repair processes, as well as for various metal parts in other industries.

With a working chamber size of 1300 x 1500 x 1000 mm, our furnace enables the heat treatment of large components, meeting the strictest industry standards.

The SECO/WARWICK VECTOR® vacuum heat treatment furnace is a single-chamber, horizontally arranged, gas-cooled system.