Control Systems

The Control Systems division performs the electrical and mechanical assembly of control cabinets for aeroderivative gas turbines.

Aeroderivative gas turbines use advanced aircraft engines and space technology. Compared to heavy frame gas turbines, aeroderivative gas turbines are usually higher in speed, broader in operating speed range, lighter, have lower air flow, faster in start-up, and need less time and spare parts for maintenance.

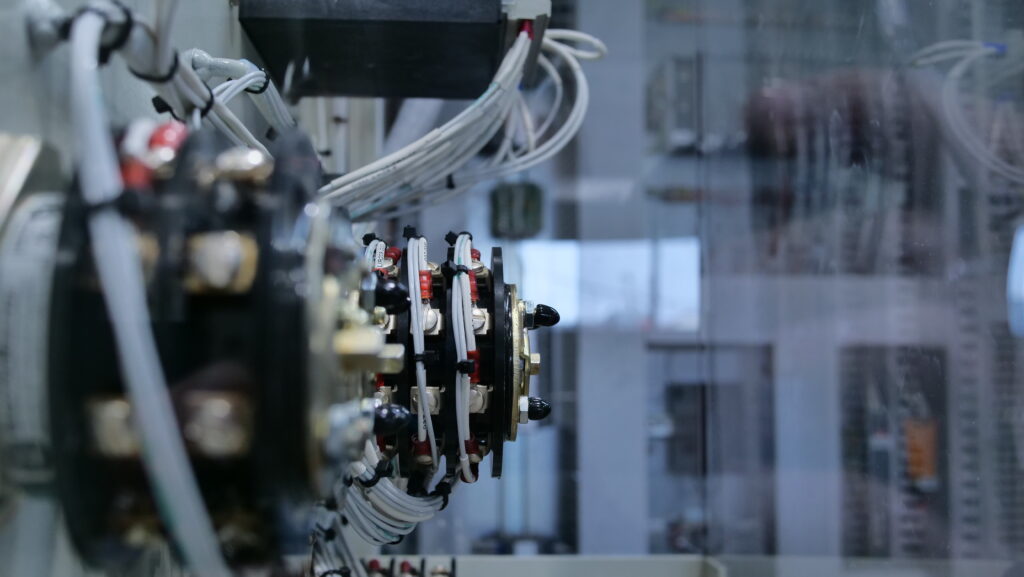

The control cabinet assembly operation starts with an overview of the 3D cabinet drawings. Based on the technical drawings, the physical work starts with cable preparations by cutting them to the desired length, then stripping and crimping the cable lug or sleeve to the wire end.

The work continues with mechanical assembly of parts inside the cabinet, then the installation of electrical modules and various types of elements. Finally, the previously prepared wires are installed, creating a fully connected control and diagnostic system inside the cabinet.

The final operation is the 100% quality check of the cabinet by screening of every element and connection.

Our capabilities

Control cabinets

The Turbine Control Panel (TCP) is the central unit for controlling a gas turbine, overseeing and managing all aspects of its operation. This control cabinet is responsible for starting the turbine, regulating its load, and ensuring safe and efficient operation.

The TCP is essentially an automated system that collects real-time data, analyzes it, and adjusts the operation accordingly.

Junctions boxes

Our company manufactures ATEX-certified junction boxes for gas power plants, designed to meet the strict regulations of hazardous environments, ensuring safe and reliable operation.

Our expert team provides customized solutions tailored to our clients’ specific needs, contributing to the success of our partners. With our fast and efficient service, along with competitive pricing, our partners can be confident that they are receiving the best value-for-money products

Our capabilities