Engine Component Repair

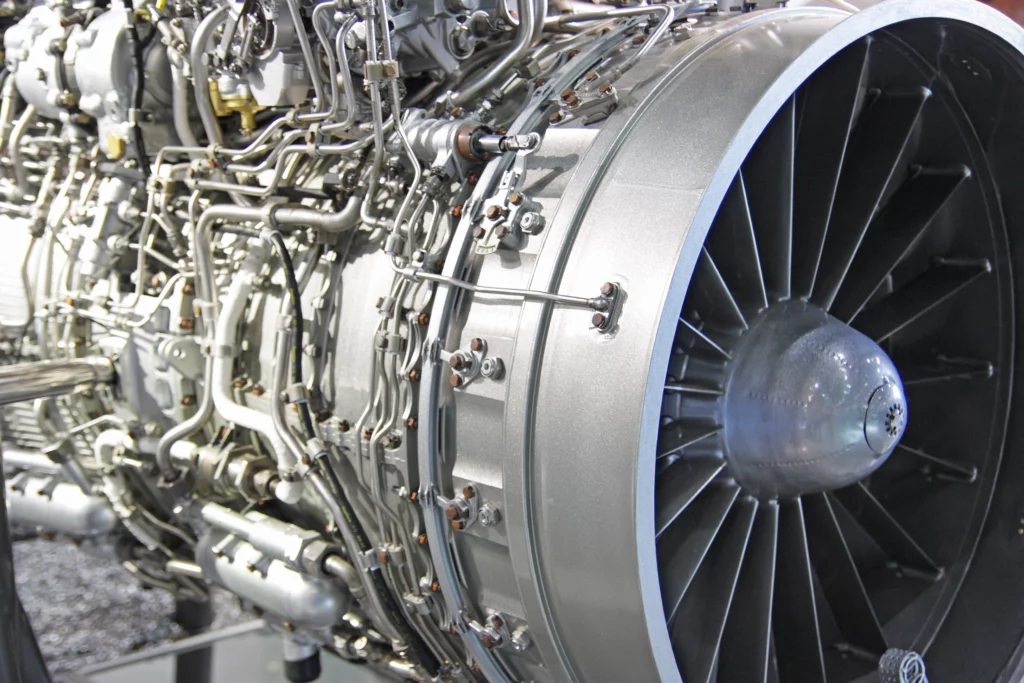

With more than a hundred years of experience in metalworking, Aero Space Power aims to take an emerging position in the component repair area. Our highly experienced team strives to meet the needs of more customers in the world of MRO with its evolving infrastructure. We are constantly expanding our currently available technologies.

We will soon expand our existing experience in cleaning, inspection, non-destructive testing, metalworking, surface treatment, welding, and measurement technology with non-conventional machining, heat treatment, and thermal spraying.

Aviation Engine Component Repair, Cleaning & Serviceability Inspection.

Our capabilities

Metallic Vane Repair

ASP offers an overhaul of aluminum alloy CFM Outlet Guide Vanes, including the incoming serviceability inspection by non-destructive material tests and dimensional checks, mechanical surface treatments (dry abrasive blasting, shot peening), high-strength precision painting of the vanes in a tangible size of painting booth (3420x3420x2800 mm). Furthermore, the installation of self-made SPD bushings in the vanes.

Thanks to our unique capability, we can perform the repair of unserviceable parts due to the condition of the attachment holes by the application of epoxy adhesive cross-linked polymer required by the OEM repair (REP013) thus ensuring a high (90%) yield. Due to the high stock of spare parts, we can keep the turnaround time within 18 days.

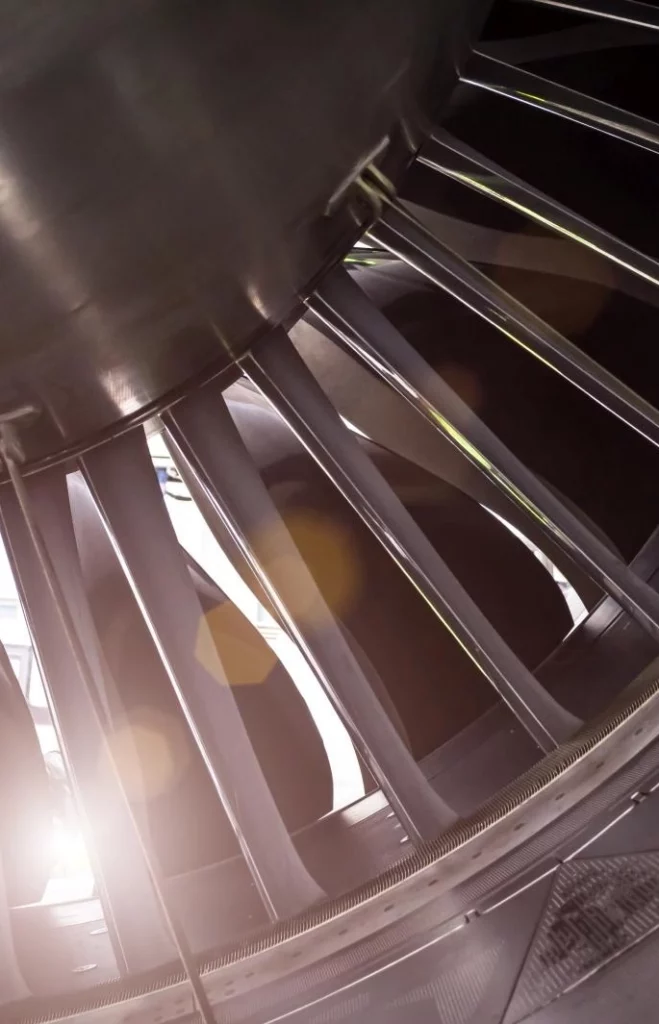

Composite Vane Repair

Outlet Guide Vanes (OGVs) play a crucial role in maintaining the efficiency and reliability of modern aircraft engines. These components, often made from composite materials, direct the airflow propelled by the fan, contributing to the engine’s optimal performance. However, during continuous operation, OGVs are susceptible to various forms of damage, including erosion, corrosion, and structural impairments, which can diminish the engine’s efficiency and dependability.

Repairing and refurbishing OGVs require specialized techniques and materials to restore their composite structures. The repair process may involve removing damaged layers, applying new composite materials, and performing surface treatments to reinstate the original aerodynamic profiles and structural integrity. These repairs not only extend the engine’s lifespan but also offer a cost-effective alternative to complete component replacement.

Due to the unique properties of composite materials, repairing OGVs can be challenging. Therefore, it is essential that such repairs are conducted by professionals with in-depth knowledge of composite material behavior and the latest repair technologies. By employing appropriate repair procedures, OGVs can be restored to meet original design specifications, ensuring the engine’s long-term, reliable operation.

Our capabilities

Our capabilities

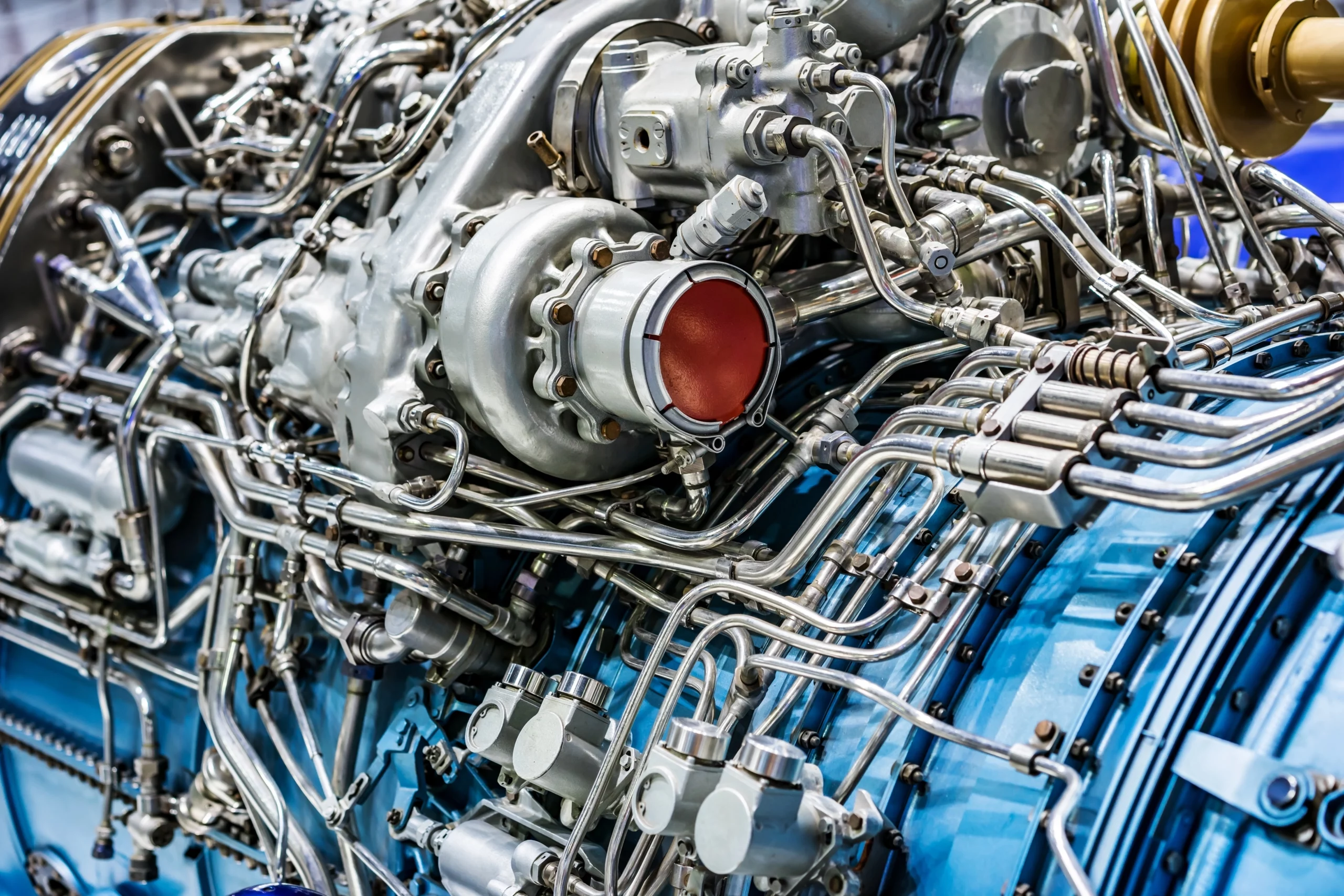

Tubes & Ducts & Manifolds

ASP offers an overhaul of tube kits and standalone tubes, ducts, and manifolds per the corresponding OEM manuals. As part of the variety of conditions, many repair solutions are available, such as tube fitting, tube section replacement by brazing & welding, ball mandrel bending, and hydraulic pressing. By having a comprehensive consignment stock established, a wide variety of OEM SPD parts are available, enabling ASP to perform most special repairs, too. Testing & inspection is an organic part of standard repair processes, hence hydraulic pressure test is done in a wide range of pressures 12psi-6000psi (0.8bar–413bar) by multiple testing media per AMS2615, as well as non-destructive testing such as visual testing & fluorescent penetrant inspection. Thanks to the high stock of the parts listed in our capability list, we can keep the turnaround time within 18 days.

Our company, Aero Space Power, guarantees:

Proper cleaning and inspection of key components, keeping in mind that damaged components can result in leaks that may jeopardize engine operation and passenger safety.

Perfect pipe repair, for which we use a wide variety of tools and fixtures to hold the various bends and special fittings in the correct position to ensure the pipes are being repaired perfectly.

LPT Cooling Manifold

Low-Pressure Turbine (LPT) cooling manifolds are essential for regulating temperatures within aircraft engines, ensuring critical components receive adequate cooling to prevent overheating. These components are subject to thermal fluctuations, mechanical stresses, and corrosion, which can compromise their structural integrity and reduce engine reliability.

Repairing damaged LPT cooling manifolds requires specialized welding techniques and materials to restore system integrity. Precision in these repairs is vital to prevent leaks and maintain efficiency, enhancing turbine performance and extending its service life. Therefore, such repairs must be conducted by experienced professionals familiar with the latest industry standards and technologies.

Our capabilities

Our capabilities

Base Maintenance Welding

In addition to our MRO activities, we provide on-site maintenance services at the Budapest and Debrecen airports. We aim to perform these tasks with maximum flexibility and speed, minimizing aircraft downtime and ensuring continuous operation. Our specialists are certified to repair all metal components of the aircraft fuselage.