Welding Solutions

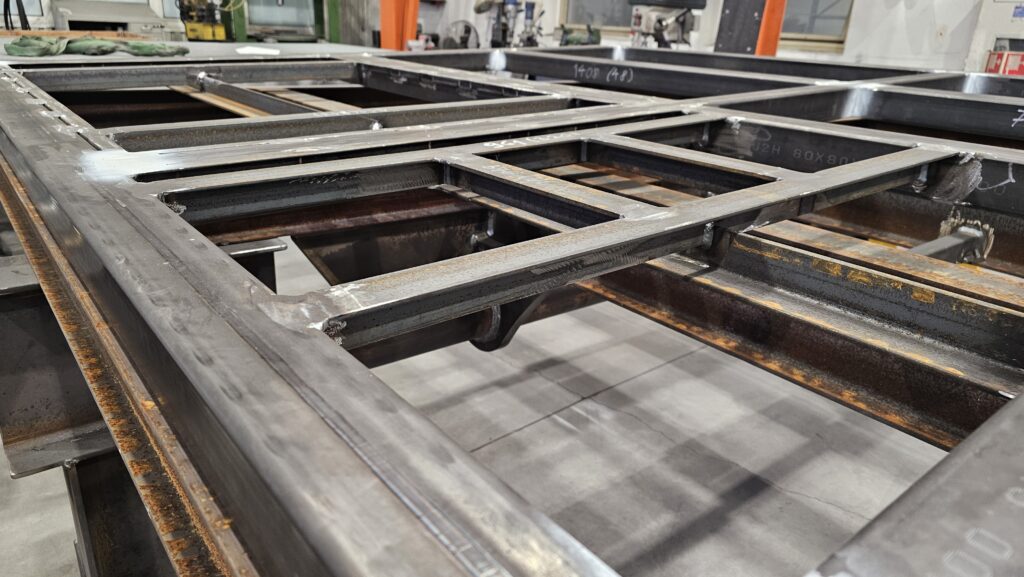

Aero Space Power provides excellent welding work of non-alloy steel, stainless steel, and aluminum alloys according to the highest quality standards. Our plant and employees are ready for projects of varying sizes of welded structures, with the maximum dimension being 12 000×5 000×2 800 mm and weighing up to 5 tons. Our welders are TÜV certified for PA, PB, PF welding positions. We pay keen attention to training our staff and developing our equipment to provide a service in compliance with our partners and international standards.

CERTIFICATIONS

ISO 9001: 2015

ISO 15614-1

ISO 15614-2

ISO 9606-1

ISO 9606-2

ISO 3834-2

ISO 1090-1 & 2

Our customers are industry leaders in renewable and conventional energy, as well as the medical sector.

Our capabilities

Large Welded

Structures

The construction of the GE LM2500 gas turbine control house was our company’s largest project to date, presenting numerous challenges, particularly in the field of welded structures. During the welding of the structural elements, adhering to strict tolerance limits was essential for precise fitting, as even the smallest deviation could affect the assembly of doors and other components. The project placed significant emphasis on non-destructive testing of the weld seams to ensure the structural integrity and long-term reliability of the unit. Additionally, minimizing and managing distortions occurring during the welding processes was crucial to preventing structural deformations and ensuring the project’s successful completion.

Our company also specializes in the design and manufacturing of custom large-scale welded walkways, grates, platforms, and railings, with Ge Vernova Off shore Wind being one of our key partners. Our comprehensive services include the full-scale execution and delivery of such structures. We are highly adaptable to our clients’ unique needs, providing tailor-made solutions to ensure customer satisfaction.

Small & Medium Welded Structures

We have extensive experience in the comprehensive manufacturing of small and medium-sized welded structures, adapting to even the most unique customer requirements. Our services cover the following areas:

- Design and Development: We utilize modern design tools and technologies to deliver innovative, custom solutions tailored to our clients’ specific needs.

- Welding and Manufacturing: Our state-of-the-art machinery and highly skilled welders ensure the production of precise and durable welded structures, whether for custom projects or series production.

- Processing and Machining: Our services include plasma and flame cutting, edge bending, sheet cutting, and rolling, meeting a wide range of metalworking needs.

- Surface Treatment: To enhance durability and aesthetics, we offer various surface treatment options such as painting, galvanization, and other corrosion protection solutions.

- Quality Control: Each of our products undergoes a strict quality control process, ensuring compliance with international standards and customer expectations.

Thanks to our flexibility and customer-centric approach, we can quickly adapt to changing market demands and provide tailor-made solutions for our partners. Whether your project involves simple or complex welded structures, you can rely on us through every stage—from design to execution.

Our capabilities