Welding skills – human resources

Welding skills

- International welding engineer (EWE, IWE)

- Materials used: carbon steel, Aluminium, stainless steel

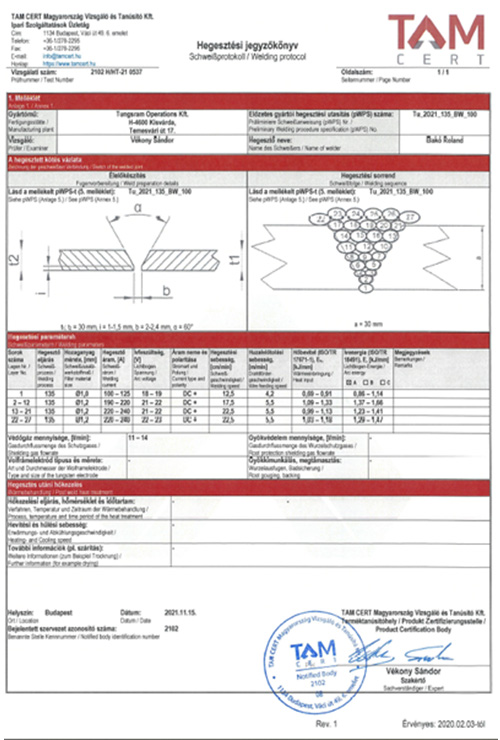

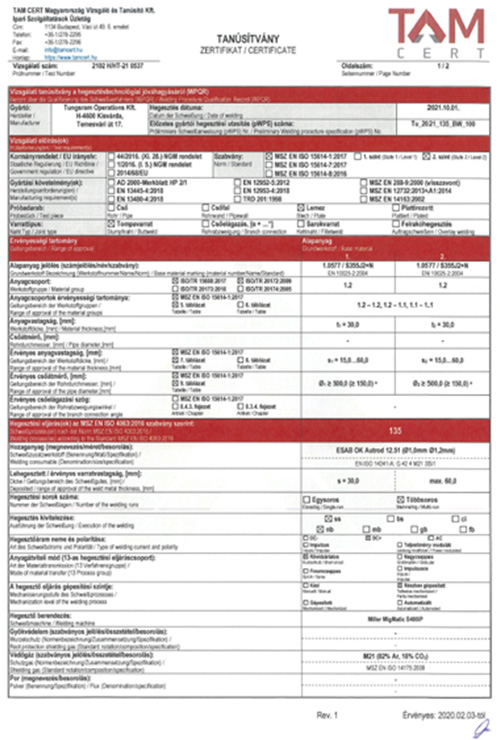

Welding process: 135 (MAG)

- Material thickness:

- Corner weld above 3.0 mm

- Blunt suture 3.0 – 60.0 mm

- Tube Ø3.0-40.0 × 3.0-24.0 mm

Welding process: 141 (TIG)

- Material thickness:

- Tube blunt Ø0.75-6.4 × Ø0.75-6.4 mm

- Cope tube Ø1.05-16 x 0.75-24 mm

Welding process: 131 (Aluminium), 141 (TIG)

- Blunt 3.0-10.0 mm of thickness

NDT technologies

- VT: visual testing Level 2, on site

- UT-MT: ultra-sonic testing & magnetic-particle testing, with contractor

Welding skills – equipment

- Material handling: In the area of the welding plant, modern equipment supports safe and efficient work. The entire operating area is covered with a 3.2 t overhead crane. Material handling is supported by factory mobile electric and backhoe cranes.

- Welding tables: The Sigmund welding tables are professional plasma nitrided tables in sizes 2000 x 1000 and 4000×2000 mm.

- Welding equipment: Miller and Iweld industrial, water-cooled, synergic (MigMatic S-400, XPS-450) equipment

- Portable fume extractors: We ensure worker safety with the necessary welding clothing, welding helmet and mobile fume extractors for each welding booth.